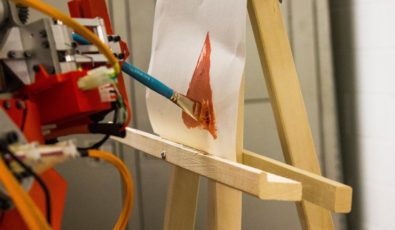

Virtually controlled robots could aid the Darlington Refurbishment

It may sound like science fiction, but a new human-to-robot interface could soon allow OPG workers to virtually control machines that perform tasks on the Darlington Refurbishment project.

The new technology, dubbed IRIS, is the brainchild of Toronto-based start-up Taiga Robotics. With almost no training, operators can put their mind into the body of a robot using a virtual reality and motion tracking interface, a concept the company calls “telereality.”

The innovative tech wowed judges at the OPG Ignite pitch competition last December, taking home first prize and $25,000 in the Darlington Refurbishment category. Now, the company is using the seed funding to develop the IRIS control system, with the goal of building a more complete prototype robot in the near future, said Dmitri Ignakov, Taiga’s co-founder and CEO.

“Anywhere you need dexterity and intelligence, we can now send in a robot virtually controlled by a human,” Ignakov said. “We want to demonstrate how our system can be used by OPG in any environment where the work is hazardous or strenuous.”

Ignakov and his colleagues are now working with OPG’s Darlington Refurbishment team to detail the ways in which IRIS can help the project. The technology would allow workers to perform difficult tasks in various environments without being exposed to radiation, and could allow for a quick response to situations that would prevent costly downtime.

IRIS makes robots dextrous, much more dextrous than what is available now, he said. The technology would allow robots to work where others aren’t able to, and could reduce total dose of radiation for workers.

“We’re excited and pleased to be part of helping Taiga Robotics develop the IRIS System,” said Michael Trudeau, Project Manager, Retube and Feeder Refurbishment Innovations on the Darlington Refurbishment. “Not a day goes by where we don’t envision new applications here at the Darlington Refurbishment project where an ‘Intelligent Manipulator’ with this advanced dexterous capability can be used, now and into the future of nuclear.”

Ignakov’s team came up with the idea after reading about Fukushima workers in Japan and the challenges they were facing using robots at the clean-up site. With current technology, it’s often difficult to control and know exactly what robots are doing. IRIS solves this problem by giving the operator direct control and immediate visual feedback through a virtual reality headset and motion controls.

“With IRIS, when I move my arm, the robot moves its arm. What the robot sees, I see.”Dmitri Ignakov, co-founder and CEO of Taiga Robotics

“Robots are perfectly capable mechanically, but it’s the way that we interface with them that gives people difficulty,” Ignakov explained. “With IRIS, when I move my arm, the robot moves its arm. What the robot sees, I see.”

The patent-pending system uses a combination of proprietary software and hardware and can be attached to any electrically controlled equipment, giving IRIS multiple applications outside of generating stations. For instance, police departments could outfit bomb disposal robots with the system, and fire departments could also use the technology for search and rescue efforts in dangerous conditions.

Currently, the Taiga Robotics team is busy developing their “robot avatar” out of the Design Fabrication Zone, a project incubation office located at Ryerson University, with the aim of developing a complete robot that could serve OPG’s needs specifically.

“I think the part I’m most excited about is that we get to continue working with OPG on developing our proposal further,” Ignakov said.

Using virtual reality to control robots

Taiga Robotics' IRIS interface puts an operator's mind into a robot's body

Subscribe and stay informed

Sign up to receive the latest news, project updates, and event information from OPG.