16-year overhaul now underway at R.H. Saunders hydro station

At a glance

- OPG’s R.H. Saunders Generating Station in Cornwall undergoing 16-year, 16-unit overhaul.

- Part of OPG’s overall commitment to refurbish units across its hydroelectric fleet.

- Project will help secure decades more clean, reliable power from Ontario’s second-largest hydro station.

In Cornwall, an extensive 16-year overhaul of Ontario’s second-largest hydroelectric station is now underway to help secure decades more reliable, clean power for Ontario’s future.

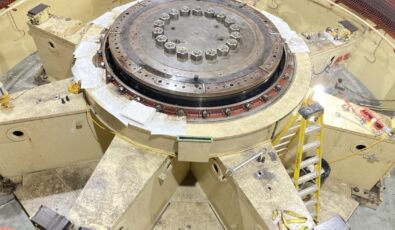

The project to overhaul all 16 units at OPG’s R.H. Saunders Generating Station (GS) kicked off in January, with the first unit, G9, now fully disassembled. The G9 refurbishment is set to be completed by early 2024, with overhauls on the rest of the hydro giant’s units occurring each subsequent year to wrap up the project by around 2039.

The initiative is part of OPG’s overall commitment to invest and revamp turbine-generator units across its hydroelectric fleet. This work will ensure OPG’s 66 hydroelectric stations in Ontario can continue to deliver clean, reliable electricity to support the province’s growing economy and demands from electrification.

Situated on the St. Lawrence River as part of the larger Moses-Saunders Power Dam shared with the U.S., the 1,045-megawatt R.H. Saunders GS has played a significant role in providing baseload generation for Ontario for 65 years.

It was last overhauled in the 1990s to early 2000s.

“When it’s all said and done, the station will be performing much more efficiently, making clean electricity from less water. And the project will have created significant economic benefits for Ontario and the local community.”Mike Woodcock, Senior Manager of Maintenance and Production at OPG

“We expect a lot of learning to take place on this first unit overhaul, which we will carry over to each subsequent unit,” said Mike Woodcock, Senior Manager of Maintenance and Production. “When it’s all said and done, the station will be performing much more efficiently, making clean electricity from less water. And the project will have created significant economic benefits for Ontario and the local community.”

Each unit overhaul will involve hoisting out and replacing the massive, 62-tonne turbine runner, which includes the steel blades that help convert rushing water into electricity. The old runners will be replaced with newer, more efficient designs that will require less water to generate power.

Another priority will be replacing the round throat ring liner, an embedded part that the turbine runner spins inside of, with a more adjustable design to deal with a unique, concrete growth inside the units that can deform the liners over time.

The phenomenon, called Alkali Aggregate Reactivity, is a rare construction oddity found in hydro stations around the world involving a chemical reaction in concrete when certain aggregates are used. Over time, swelling from this reaction can cause expansive pressure that could interfere with the movement of the turbines.

Beyond this work, each overhaul will also involve installing new servo motors and thrust bearings, setting up new electrical systems, and completing a lot of machining, welding, and painting of the various generator and turbine components.

As this work hasn’t been performed in decades, several experienced OPG employees who were around for the last overhauls are helping to mentor workers while sharing their knowledge and expertise.

The project is looking outside for help as well, through contractors, original equipment manufacturers, and local businesses.

“We’ve reached out to people from the Cornwall community for support, hiring local vendors and suppliers, including two Cornwall-based metal fabricators,” said Codie Lonsberry, Project Site Manager at R.H. Saunders.

An Indigenous company based out of Desoronto has also been contracted to sandblast, repair, and repaint several working platforms needed for the G9 overhaul, which supports OPG’s Reconciliation Action Plan goals.

“We are striving to utilize as many local companies as we can particularly from Cornwall and across the province,” said Lonsberry.

Subscribe and stay informed

Sign up to receive the latest news, project updates, and event information from OPG.