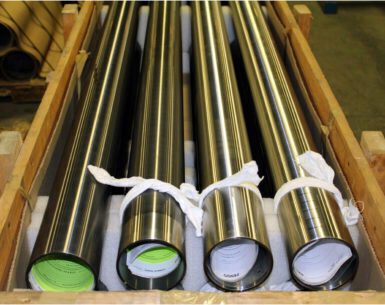

Nu-Tech delivers the tubes for Darlington Refurb

An Arnprior company has delivered important pressure tubes required to refurbish the Unit 2 reactor at the Darlington Nuclear Generating Station.

Nu-Tech Precision Metals, which manufactures pressure tubes used in CANDU reactors, recently shipped 513 of the tubes (480 for the reactor and 33 spares) ahead of schedule and on budget.

The small eastern Ontario metal fabricator also produced the original pressure tubes that were installed when Darlington Nuclear was first constructed.

“Since 1957, every pressure tube in an operating CANDU reactor worldwide has been made by Nu-Tech,” said George Legate, Nu-Tech president. “We’re proud to have been trusted to manufacture this very important component when Darlington was first built and again for its continued operations.”

The pressure tubes made by Nu-Tech include zirconium metal that comes from deposits found in the sandy beaches of Australia.

Each pressure tube sits inside a calandria tube within the reactor. And inside each pressure tube sits the nuclear fuel bundles that make clean, reliable nuclear power. This design enables the use of online refuelling, which is a unique feature of CANDU reactors.

Nu-Tech is one of many companies from across Ontario directly engaged in the Darlington Refurbishment. With approximately 96 per cent of the project’s suppliers based in the province, this is a truly made-in-Ontario story.

On May 4, a special ceremony was held at Nu-Tech to announce the shipment to the Darlington power plant.

“Nu-Tech makes something very important to making a reactor run — pressure tubes,” said Roy Brown, Senior Director for Darlington Refurbishment. “But they just don’t make a product. This company and every employee ensure the safety of our operations and the safety of the public.

Subscribe and stay informed

Sign up to receive the latest news, project updates, and event information from OPG.