R.H. Saunders GS now back to full strength after successful unit repair

All 16 units at OPG’s R.H. Saunders Generating Station (GS) in Cornwall are once again reliably producing clean power for Ontario, as they have done for more than 60 years.

Last July, the 66-megawatt (MW) unit experienced a thrust bearing failure, an important piece of equipment that keeps the turbine spinning to generate clean electricity. In January, during an outage to replace the bearing, the maintenance team at the hydro station received a request to expedite the repair by a full month to take advantage of forecasted high water levels on the St. Lawrence River.

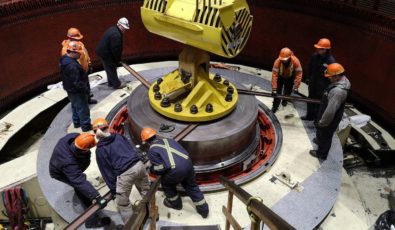

Through a focus on safety, teamwork and help from OPG employees from other stations and regions, the G7 unit was brought back into service on March 26, one month earlier than originally scheduled. It is now harnessing increased water flows this spring and will be available to help power Ontario’s economic recovery from the COVID-19 pandemic.

“It was great to see new faces at the station in an environment where you could learn from one another,” said Codie Lonsberry, Project Manager on the G7 outage. “We could not have accelerated the return to service without the extra help.”

A total of 26 supplemental OPG employees from various sites across the Renewable Generation division were brought in to provide support on the project over six weeks, including mechanical and electrical staff.

The onset of the coronavirus outbreak added to the logistical and planning challenges, as workers followed new safety protocols to protect themselves and their colleagues through physical distancing and other measures.

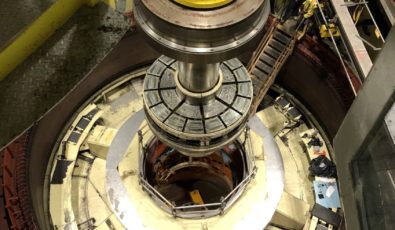

Work on G7 involved disassembling the upper portion of the unit and installing a Teflon-based thrust bearing, the first time this kind of bearing has been used at the 1,045 MW station. This new design will reduce bearing friction, increase thrust capacity, and improve turbine reliability in the unit.

“It was great to see new faces at the station in an environment where you could learn from one another. We could not have accelerated the return to service without the extra help.”Codie Lonsberry, Project Manager on the G7 outage

Fortunately for the team, the station recently undertook a similar bearing outage on another unit last year. The lessons learned from this previous repair proved invaluable for planning, safety, productivity, and other improvements on G7, and will help with planning on unit overhauls at the station set to begin in 2022.

“The successful installation of this newly designed component not only ensures G7’s reliability, but also verifies the design application for subsequent station unit overhauls,” said Matt Shaw, Mechanical Trades Management Supervisor at R.H. Saunders GS.

Subscribe and stay informed

Sign up to receive the latest news, project updates, and event information from OPG.