OPG successfully defuels second reactor on Darlington Refurbishment Project

Four years after successfully defuelling the first unit to undergo refurbishment at the Darlington Nuclear Generating Station (GS), OPG has completed its second defuel campaign ahead of schedule, allowing for the next phase of the Darlington Refurbishment Project to begin.

“Once again, the Darlington Fuel Handling team has demonstrated their knowledge, skills and expertise, defuelling Unit 3 safely and with quality ahead of the targeted completion date,” said Steve Gregoris, Senior Vice President, Darlington Nuclear GS.

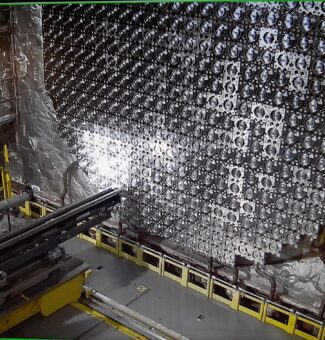

Scheduled as a 90-day campaign, defuelling involves the remote-controlled removal of 6,240 fuel bundles from the reactor. These removed components are then placed in water-filled fuel bays, where they remain in safe storage for up to 10 years.

With Unit 3 defuelling now complete, OPG and its project partner, CanAtom Power Group, have begun to prepare the reactor for disassembly, a series of work that starts with Islanding.

“Islanding is how we create a safe and defined work area for refurbishment, protecting workers and the plant,” said Subo Sinnathamby, Senior Vice President, Nuclear Refurbishment. “Over the course of 55 days, we’ll separate the unit being refurbished from operating units by implementing controls and installing steel bulkheads.”

“Over the course of 55 days, we’ll separate the unit being refurbished from operating units by implementing controls and installing steel bulkheads.”Subo Sinnathamby, Senior Vice President, Nuclear Refurbishment

Though OPG has already refurbished and returned one unit to service, Unit 2, the project team isn’t looking at the refurbishment of the next units as simply a repeat of the first.

“The benefit of having already refurbished one unit is the ability to apply that direct experience to the remaining work,” added Sinnathamby. “We're making sure to build on our success by applying more than 4,000 lessons learned to the plans and preparations for the refurbishments of Units 3, 1 and 4. And we’ve already started to see efficiency gains in schedule and quality performance.”

The four-unit Darlington Refurbishment Project is scheduled for completion by 2026.

Subscribe and stay informed

Sign up to receive the latest news, project updates, and event information from OPG.