Final stages of Unit 2 reactor construction underway

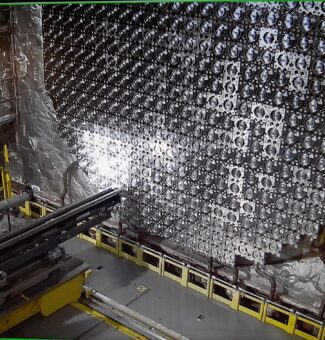

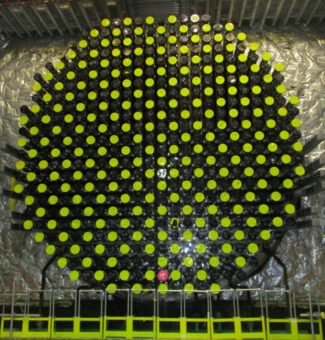

One of the critical steps in the Darlington Refurbishment project is the installation of 960 new feeder tubes inside each of Darlington Nuclear Generating Station’s four reactors.

This past spring, OPG and its project partners successfully installed upper and middle feeder tubes on Unit 2, and the installation of lower feeder tubes is currently underway with completion targeted for early October.

Feeder pipes are vital to the safe operation of a nuclear reactor as they carry the coolant required to cool nuclear fuel.

“Feeder tube installation is a complex process that has historically been a challenge on nuclear refurbishment projects around the world,” said Dietmar Reiner, OPG’s Senior Vice President, Chief Project Officer. “We’ve experienced challenges on the work series, but are making great strides in improving performance by applying lessons learned, tackling issues head-on and working collaboratively with our project partners.”

Each reactor feeder tube is unique in shape, size and length and needs to be installed in a correct sequence. Because of their composition, installing them is a process similar to putting together hundreds of puzzle pieces. Combined with limited and awkward workspaces inside the vault, feeder installation requires highly detailed logistics planning and in-depth worker training.

“Feeder tube installation is a complex process that has historically been a challenge on nuclear refurbishment projects around the world.”Dietmar Reiner, OPG’s Senior Vice President, Chief Project Officer

Once lower feeder installation is complete, the project team will start loading 6,240 new fuel bundles, manufactured by BWXT Canada, into the reactor – a critical step on the road to restarting the unit.

On the horizon: Unit 3 refurbishment

OPG and its project partners started the execution phase of the Darlington Refurbishment project in October 2016. Since then, more than 90 per cent of the construction work on Unit 2 has been completed and 37 of 58 major plant systems have returned to service. At the same time, OPG has been actively working on the planning and preparation for the refurbishment of Unit 3.

“Design and engineering plans for Unit 3 are now more than 90 per cent complete, and materials are being delivered from our suppliers,” said Jeff Richardson, OPG’s Senior Vice President of Nuclear Projects. “We’re building on the successes of the first refurbishment by applying learnings from Unit 2 to our plans for Unit 3 and subsequent units to achieve improved performance and greater cost savings and efficiencies.”

Unit 3 is scheduled for refurbishment starting in 2020.

Subscribe and stay informed

Sign up to receive the latest news, project updates, and event information from OPG.