Darlington Refurbishment tool testing underway

With the Darlington refurbishment just over 100 days away, preparations are in full swing. Employees are now going through extensive tool testing, working in Darlington’s mock-up reactor as a “dry run” for the project itself.

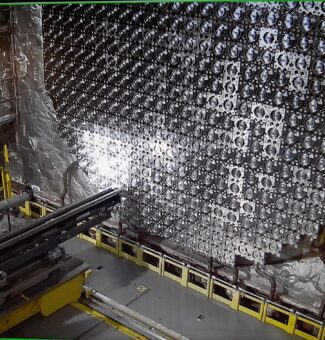

The mock-up is an exact replica of a Darlington CANDU nuclear reactor, right down to its eight-metre-high reactor face. It comes complete with all the components employees will be working to replace or refurbish, including 480 fuel channels, feeder tubes and fuel channel assemblies. The first of its kind in Canada, it has been installed at the Darlington Energy Complex to give workers the best possible preparation for the project.

The training has been designed to be as realistic as possible. Wearing full protective gear and hooked up to a supply of oxygen, each of the workers will get a clear understanding of the complexities and simulated environment of working inside the actual Darlington reactor vault.

The training has been designed to be as realistic as possible. Wearing full protective gear and hooked up to a supply of oxygen, each of the workers will get a clear understanding of the complexities and simulated environment of working inside the actual Darlington reactor vault.

It’s incredibly thorough preparation. Every piece of equipment used for the refurbishment –from tiny hand tools to a 100,000-pound work platform—is being tested for optimal performance and reliability.

“The mock-up gives workers the best possible training for the refurbishments,” says Roy Brown, OPG’s Senior Director of Nuclear Projects. “This project is an integral part of Ontario’s future energy portfolio, and it’s essential we’re proactive in our preparations. This isn’t just a power plant –it’s an investment in our province.”

Training will focus on the challenges, constraints and potential hazards employees may face when executing work at the reactor face. It gives employees the ability to practice techniques, test procedures and processes and familiarize themselves with the tools and working conditions before entering the real reactor during refurbishment.

“It’s not just a benefit to long-time nuclear veterans,” adds Brown. “The mock-up also provides an authentic experience for workers who have never been in a reactor before. This inside knowledge will be essential when the real refurbishment kicks off on October 2, boosting economic activity an average of 8,800 jobs over the life of the project.”

This $12.8-billion investment is expected to generate $14.9 billion in economic benefits for the province. In addition to the thousands of construction jobs created at the station, the project will involve some 60 Ontario major companies and contractors supplying components for the project. After its refurbishment, Darlington will continue to provide reliable, low-cost clean power to Ontario consumers for another 30 years.

Subscribe and stay informed

Sign up to receive the latest news, project updates, and event information from OPG.