AGVs save OPG time on Darlington Refurbishment

In less than 70 days, OPG will begin refurbishing Darlington Nuclear generating station, kicking off Canada’s largest clean energy project. Expected to create 8,800 jobs during each year of construction, the project brings together more than 60 Ontario companies. With so many people and components, the need for strict coordination is crucial.

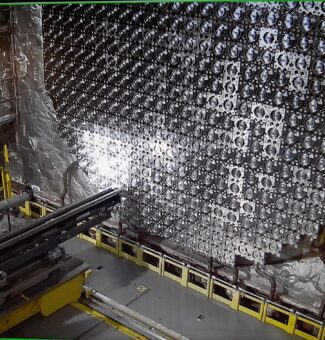

OPG’s staff and trades people are heavily focused on overseeing, implementing and monitoring an incredible number of moving parts. Approximately 70 per cent of the project’s efforts involve transporting thousands of materials and tools into and out of the nuclear reactor vault. It’s no wonder that OPG has acquired two automated guided vehicles (AGVs), a proven and innovative technology, for support.

“Essentially, they’re mobile robots,” says Roy Brown, senior director of projects (retube and feeder replacement) at OPG. “They’re usually used in the manufacturing industry to carry massive loads. However, they’ve become extremely important at Darlington.”

The AGVs are programmed to follow sensors or magnetic strips stamped onto the station’s floors. They can turn on a dime, are accurate within millimetres and allow for agility in transportation that is critically important in confined spaces, such as a nuclear reactor vault.

“They’re also very versatile,” adds Brown. “Though we purchased them to transport radioactive components, we now use them to transport, install and move large toolsets in and out of the reactor vault.”

The innovations began occurring during worker training at Darlington’s worldclass mockup reactor. The AGVs were initially used to handle flasks or containers specially designed to transport the project’s 8,800 radioactive parts and components. However, broader uses were quickly identified. Now, after thorough evaluations and process modifications, OPG is scheduled to use its AGVs in almost all of the project’s material handling.

“Thanks to the broader application of these vehicles, OPG is projecting that approximately 19 days of project time will be saved,” says Brown. “Over the course of the project, that should translate into a considerable return on investment.”

Subscribe and stay informed

Sign up to receive the latest news, project updates, and event information from OPG.