Darlington Nuclear set to supply life-saving Cobalt-60 isotopes

For close to 50 years, OPG’s Pickering Nuclear Generating Station (GS) has been a source of one of the world’s most valuable medical isotopes – Cobalt-60.

Now, OPG will continue Pickering’s legacy at Darlington Nuclear GS in Clarington.

The company has signed a new agreement with Nordion, an Ottawa-based health sciences company, to produce Cobalt-60 at Darlington’s reactors.

The life-saving isotope, used to irradiate and sterilize medical devices and equipment, as well as certain foods, helps keep millions of people around the world safe and healthy.

In addition to Cobalt-60, Darlington will soon be producing another life-saving isotope, Molybdenum-99, which helps detect illnesses like cancer and heart disease. In 2018, OPG announced the plant will be the first commercial nuclear power station in the world to produce large quantities of the isotope.

“With Darlington’s ongoing mid-life refurbishment, the station will be a steady and reliable source of medical isotopes for the next 30-plus years,” said Ken Hartwick, President and CEO of OPG. “We’re very proud of our legacy of Cobalt-60 production at Pickering and look forward to continuing this at Darlington.”

“With Darlington’s ongoing mid-life refurbishment, the station will be a steady and reliable source of medical isotopes for the next 30-plus years.”Ken Hartwick, President and CEO of OPG

Pickering has supplied Cobalt-60 since 1971 and was the first Ontario generating station to produce the isotope. With the station’s upcoming end of commercial operations, expanding Cobalt-60 production to Darlington will help Ontario continue to meet the growing global demand for this isotope.

Currently, close to 50 per cent of the world’s Cobalt-60 is supplied by Ontario’s nuclear reactors. And 40 per cent of the world’s single-use medical devices and equipment are irradiated and sterilized using Cobalt-60.

Expanding production to Darlington will result in high-quality jobs and ensure Canada remains a world-leading supplier of important radioisotopes, Hartwick said.

Cobalt-60 emits gamma radiation, which is useful in irradiating and sterilizing medical devices and certain foods, like spices, meats and fruits. This sterilization process kills harmful bacteria as well as pests and insects that may be present in food.

Currently, at Pickering, a team of skilled OPG employees extracts the isotope roughly every 24 months during unit outages at the station.

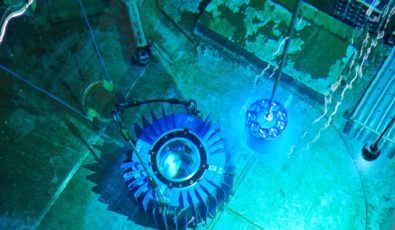

At the beginning of each cycle, rods of Cobalt-59 are placed into the reactor and then bombarded with neutrons over several months. This process turns the Cobalt-59 to Cobalt-60. The rods are then pulled from the unit and cooled in the waters of the spent fuel bay before being packaged in flasks, which are then shipped to Nordion to be processed and delivered to clients around the world.

“Cobalt-60 is one of the key lines of defence in global efforts to safeguard public health,” said Kevin Brooks, President of Nordion. “Expanding our long relationship with OPG will ensure that we meet growing global demand for this critical isotope.”

How does Cobalt-60 benefit healthcare?

Subscribe and stay informed

Sign up to receive the latest news, project updates, and event information from OPG.