Concrete cutting relieves pressure at hydro giant R.H. Saunders GS

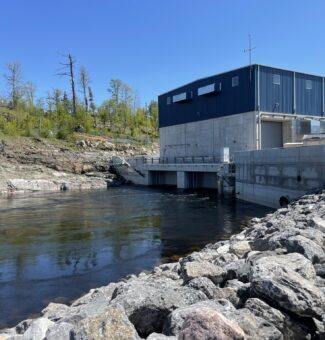

At OPG’s R.H. Saunders Generating Station (GS), 16 turbines inside the hydro giant convert the power of the rushing St. Lawrence River into clean power for Ontario.

The station has been doing this job steadily and reliably since it went into service in 1958.

But a rare construction oddity found in hydro stations around the world has threatened to snag the station’s operations. The phenomenon is called Alkali Aggregate Reactivity, or AAR, a problem that engineers first spotted at the station in the 1970s.

Essentially, AAR is a chemical reaction that occurs in concrete when certain aggregates are used. The alkali in the concrete combines with silica found in aggregates to form a gel that absorbs water and swells.

Over time, this swelling can cause expansive pressure and structural movement in the concrete. If left unchecked, this could interfere with the movement of the turbines at R.H. Saunders GS, potentially damaging units and causing major downtime for repairs.

“Essentially, the concrete swells around the turbines, deforming the round throat ring liner into more of an oval shape,” said Jen Pulikunnel, a Project Leader with OPG. “In our case, OPG responded to this by cutting thin slots in the concrete expansion joints between the generating units, which relieved some of the compressive stresses.”

This mitigating process to relieve pressure on the station’s units first took place between 1993 and 1996. This past September, another round of slot-cutting between the station’s 16 units successfully wrapped up.

With pressure building up due to concrete growth since the ‘90s, it became necessary to take action, especially as R.H. Saunders’ units are set to undergo a major overhaul in the near future, said Pulikunnel, who led the recent cutting project.

The complex job started in 2017 and took nearly two years to complete, with cutting taking place 24 hours a day for weeks on end. Contractors used diamond wire to re-cut the previously cut slots in all 16 positions.

“Essentially, the concrete swells around the turbines, deforming the round throat ring liner into more of an oval shape.”Jen Pulikunnel, Project Leader with OPG

New challenges arose as the previous access holes had to be enlarged to allow contractors to employ a new kind of concrete cutting method. The project team also had to contend with wire jamming.

Despite the challenges, the project was a success and OPG’s unique solution to the AAR issue at Saunders has been adopted by several Canadian hydro companies.

But, this is not a permanent solution. While the concrete growth has slowed in recent years at Saunders, these freshly cut slots will gradually begin to close again and will need to be re-cut in the future.

“We’re all very pleased, despite the challenges we faced. By executing this project, OPG will help to ensure Saunders’ long-term sustainability, providing reliable clean power for decades to come,” Pulikunnel said.

Subscribe and stay informed

Sign up to receive the latest news, project updates, and event information from OPG.