Darlington Unit 3 fuel channel installation is complete

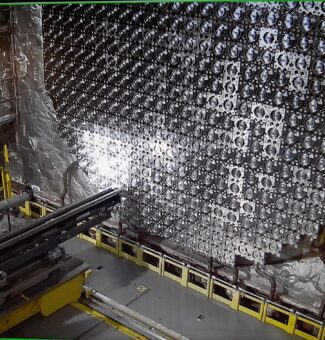

Fuel channel installation is complete on Unit 3, culminating a lengthy and complex work series resulting in the completion of the reassembly of the reactor core.

Workers completed fuel channel installation activities on Monday, July 18, 2022.

“Fuel channel installation, and the planning and coordination necessary to complete it in an efficient way with quality, is extraordinarily challenging,” said Subo Sinnathamby, OPG Senior Vice President, Nuclear Refurbishment. “We are literally rebuilding a reactor core to the highest safety and quality standards. We could not have done this without a strong and integrated OPG/CanAtom team.”

“This milestone is not just significant to Darlington Nuclear and OPG. This is also symbolic for the nuclear industry as a whole."Subo Sinnathamby, OPG Senior Vice President, Nuclear Refurbishment

Fuel channel installation is one of the more complex steps in the project. It requires the precise installation of 480 pressure tubes, 960 end fittings and thousands of other components. By incorporating more than 4,000 Lessons Learned from Unit 2, the first Darlington reactor to be completely refurbished, the critical Retube and Feeder Replacement (RFR) work on the Unit 3 reactor and associated systems is progressing ahead of schedule.

With fuel channels installed and leak tight, feeder installation continues with the lower segments and connection to each channel. Following this is fuel load later this year. The remainder of the project will focus on bringing systems back into service, testing, and ensuring the Unit is ready to produce power for Ontario’s power grid in mid-2023.

“This milestone is not just significant to Darlington Nuclear and OPG,” noted Sinnathamby. "This is also symbolic for the nuclear industry as a whole. We have again demonstrated our diligent oversight and expertise to complete this job with quality – proof that we can, and will, successfully complete refurbishment of the remaining Darlington reactors – Units 3, 1 and 4 – by the end of 2026."

On Feb. 15, 2022, Unit 1 was removed from service to begin its 39-month-long refurbishment, marking the first time that two reactors at Darlington will be in refurbishment outages at the same time.

All fuel has been removed from Unit 1 and work will soon begin to install the single largest tool used in the refurbishment project – the Retube Tooling Platforms (RTPs). Used for disassembly, inspection and reassembly of the reactor, the 45,000 kg RTP is capable of carrying materials, tooling and workers safely to every position of the 480 reactor channel locations with incredible accuracy.

Subscribe and stay informed

Sign up to receive the latest news, project updates, and event information from OPG.