Securing decades more clean power for Ontario

In 2016, after years of detailed planning and preparation, Ontario Power Generation's (OPG's) team of project partners, industry experts, energy professionals, and skilled tradespeople successfully shut down the first of four Darlington reactors scheduled for refurbishment over the next 10 years.

Explore how this ambitious initiative took place, and how the Darlington Refurbishment Project continues to progress on time and on budget.

Refurbishment timeline

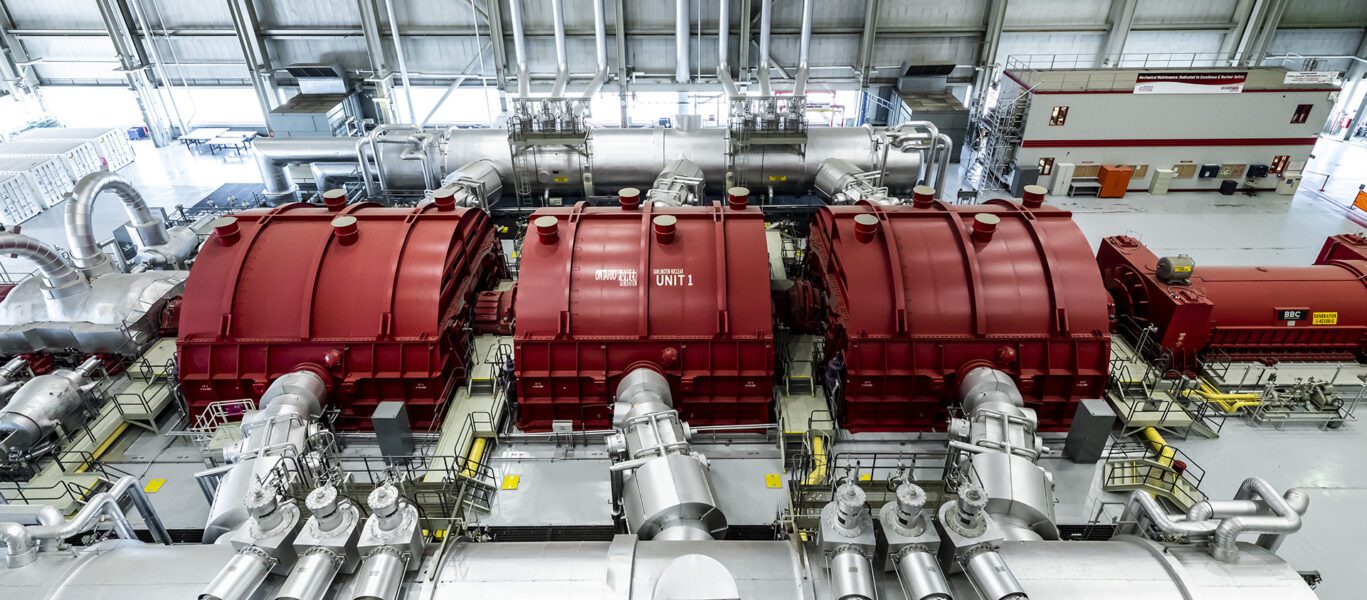

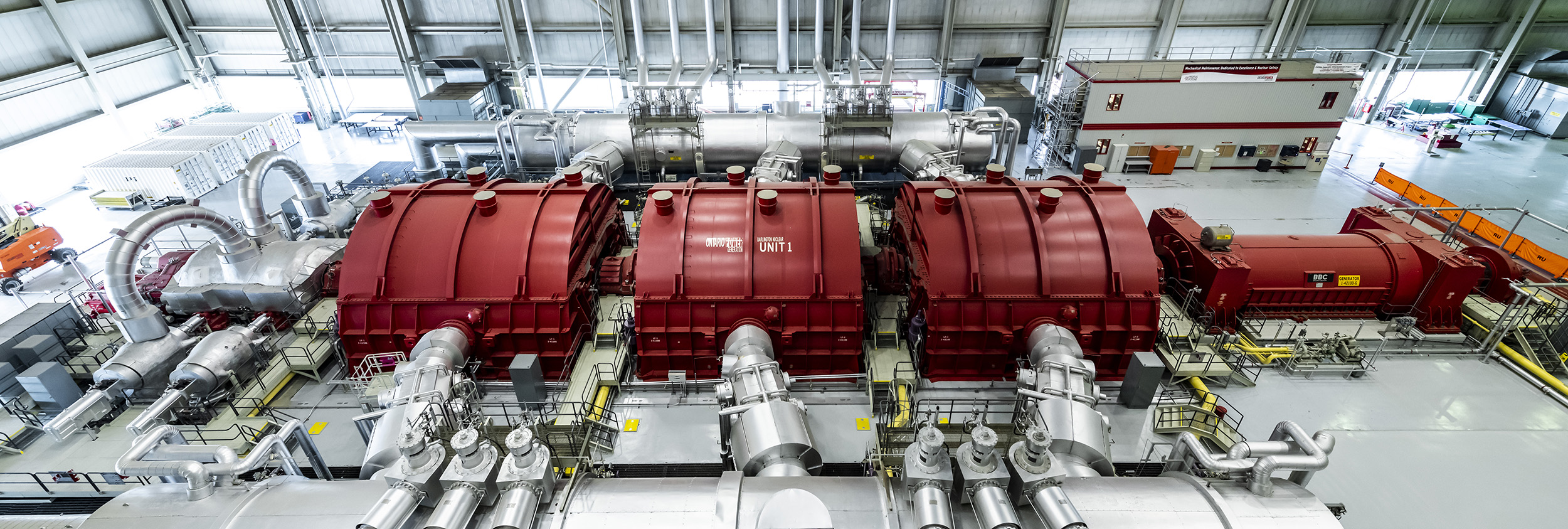

- Unit 1

- Unit 2

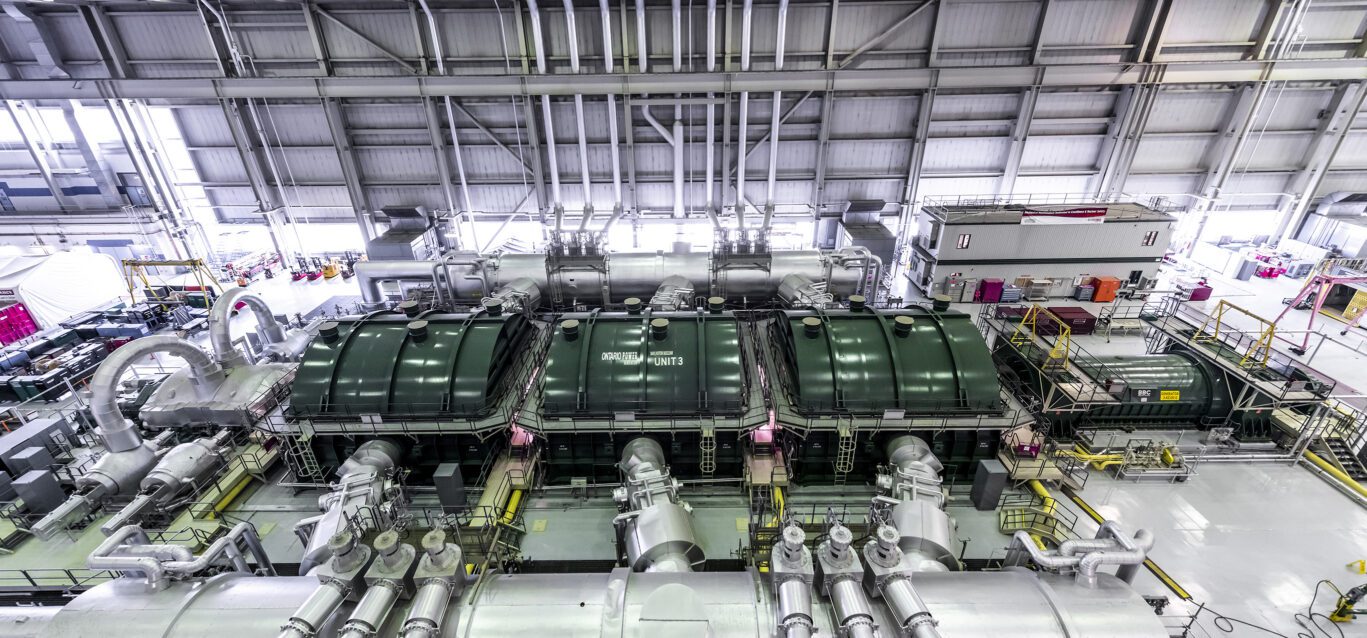

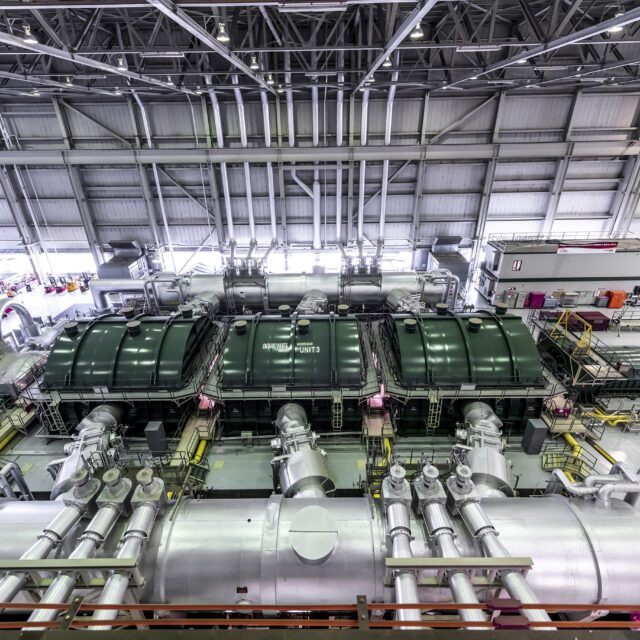

- Unit 3

- Unit 4

Following years of detailed planning, approvals and preparations, the Darlington Refurbishment Project team carries out the first major step in project execution: Shutting down the reactor and disconnecting it from the power grid. This is done through a process also known as ‘breaker open,” which involves cooling the reactor and stopping nuclear fission in accordance with Canadian Nuclear Safety Commission regulations and operational procedures.

Now that the reactor has been safely shut down and the reactor disconnected, workers use remote-controlled tooling to remove 6,240 fuel bundles from the unit and place them in water-filled fuel bays for up to ten years of safe storage. Once the fuel has been removed, workers drain heavy water from the reactor and the heat transport system, then store, clean and purify it before pumping it back in, after unit reassembly.

With the fuel and heavy water removed, the unit undergoing refurbishment must be separated from the operating plant. This is done through a process known as Islanding, whereby workers disconnect equipment and put physical barriers in place.

Islanding allows the unit to be refurbished safely and efficiently while limiting impact on the operating units and rest of the station.

Workers perform a containment pressure test at this stage to confirm that the disconnected unit has been safely and completely isolated from the rest of the operating plant.

This process involves raising the pressure in the unit to ensure that any contamination is contained.

After opening the airlocks to allow for the free movement of materials and equipment, workers remove 960 feeder tubes from the reactor.

Feeder tubes carry heated heavy water to boilers and return the water back to the reactor for reheating.

Removal of the feeders is the first step in the disassembly of

the unit, and sets the stage for replacement of parts.

Fuel channels are made of several components: a pressure tube, two stainless steel end-fittings and annulus spacers, which separate the pressure tube from the calandria tubes, preventing them from touching.

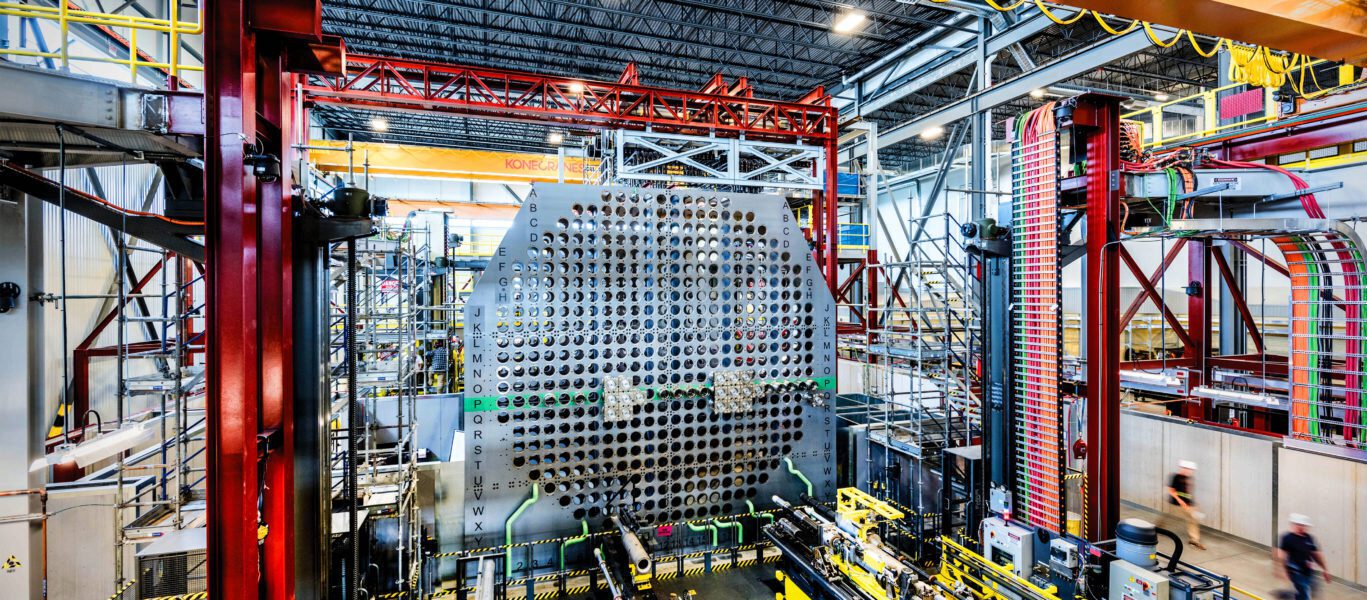

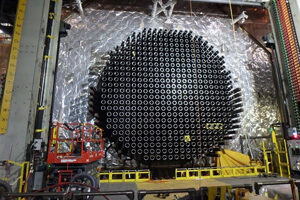

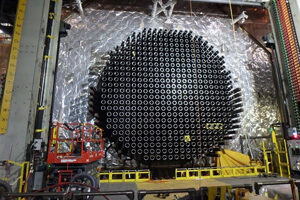

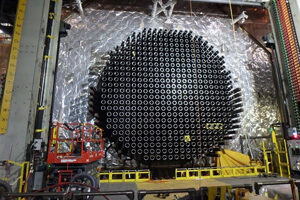

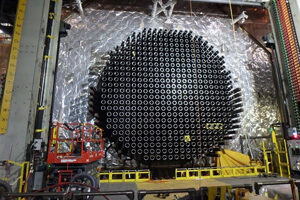

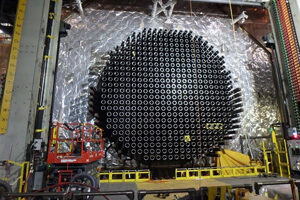

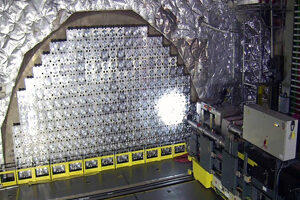

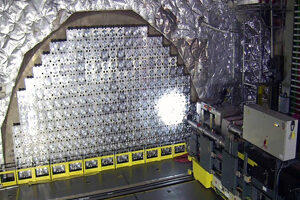

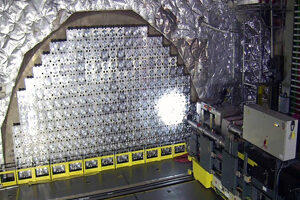

Once all end fittings have been taken out, workers remove all 480 pressure tubes through a process that involves these of engineered tooling mounted on a massive Re-tube Tooling Platform, inside the vault.

A calandria tube is a long cylindrical tube made of zirconium that surrounds the pressure tube and forms a leak tight seal of the calandria vessel – the heart of the reactor.

A Darlington CANDU reactor contains 480 calandria tubes, which are removed using specialized tooling, which workers operate remotely and transport in protective flasks to OPG’s Re-tube Waste Processing Building for storage preparation.

With all the reactor components removed, workers carefully clean and inspect the calandria vessel to ensure materials show no degradation.

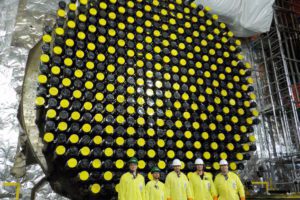

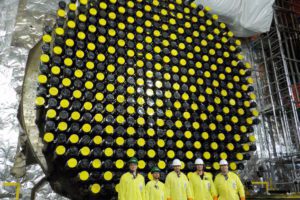

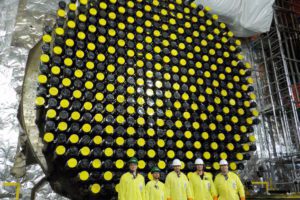

Once this process is complete, workers install 480 new calandria tubes inside the reactor.

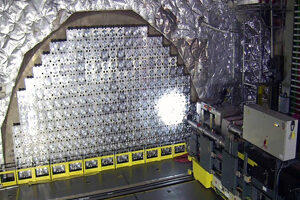

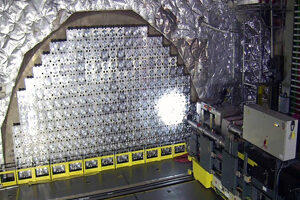

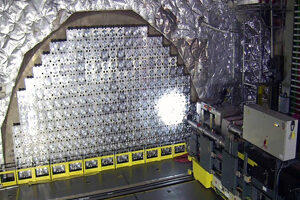

Workers complete much of this work manually and directly on the face of the reactor, with direction provided by operators in our Re-tube Control Centre.

After installation, inspection and testing, workers reattach the bellows assemblies, which allow for any movement of pressure tubes and calandria tubes, caused by temperature changes.

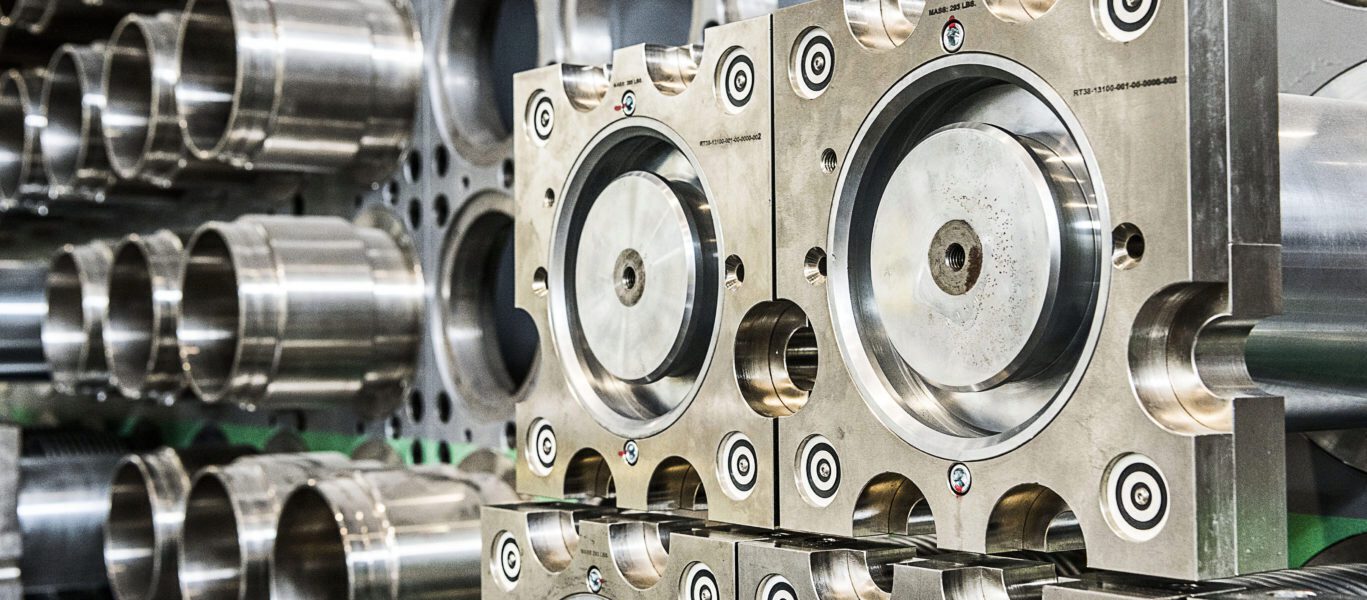

Fuel channels are made of several sub-components: a pressure tube, two stainless steel end-fittings and annulus spacers.

The reactor’s 480 fuel channels are critical parts of the heat transport system, which hold the reactor’s fuel bundles.

At this stage, workers pre-assemble the fuel channels in a climate- and foreign material-controlled clean room then prepare them for delivery to the vault for installation.

Each of the reactor’s 960 feeder tubes is unique in shape, size and length, and these new components are delivered in three sections: upper, middle and lower. Because of their unique composition, installing them inside the reactor is a process similar to putting together a puzzle.

Starting with upper section, workers install feeder tubes, making their way down to the lower section, where the feeder tubes are attached to end fittings.

Once this work is complete and regulatory approval received, the project team fills the moderator with clean heavy water and prepares to load the reactor with new fuel.

At this stage, workers refill the moderator with heavy water, load each of the 6,240 fuel bundles into the fuel channels, then fill and pressurize the heat transport system.

A fuel bundle contains natural uranium in the form of ceramic pellets.

Unit containment is restored once we’ve removed all tooling, including the Re-Tube Tooling Platform, needed to perform refurbishment; the airlocks have been closed; the physical barriers removed from inside the vault; and the 59 key systems have been returned to service.

Operators in the Re-Tube Control Centre can then begin the process of achieving first criticality, which means sustaining the chain reaction of splitting atoms and releasing heat.

Throughout refurbishment, the Canadian Nuclear Safety Commission carries out inspections and grants approvals for the project to progress from one milestone to the next. At this stage, the CNSC continues this oversight, confirming the newly refurbished unit can be operated safely and granting approval for the reactor to be gradually brought back to full power and reconnected to Ontario’s power grid.

Following years of detailed planning, approvals and preparations, the Darlington Refurbishment Project team carries out the first major step in project execution: Shutting down the reactor and disconnecting it from the power grid. This is done through a process also known as ‘breaker open,” which involves cooling the reactor and stopping nuclear fission in accordance with Canadian Nuclear Safety Commission regulations and operational procedures.

Now that the reactor has been safely shut down and the reactor disconnected, workers use remote-controlled tooling to remove 6,240 fuel bundles from the unit and place them in water-filled fuel bays for up to ten years of safe storage. Once the fuel has been removed, workers drain heavy water from the reactor and the heat transport system, then store, clean and purify it before pumping it back in, after unit reassembly.

With the fuel and heavy water removed, the unit undergoing refurbishment must be separated from the operating plant. This is done through a process known as Islanding, whereby workers disconnect equipment and put physical barriers in place.

Islanding allows the unit to be refurbished safely and efficiently while limiting impact on the operating units and rest of the station.

Workers perform a containment pressure test at this stage to confirm that the disconnected unit has been safely and completely isolated from the rest of the operating plant.

This process involves raising the pressure in the unit to ensure that any contamination is contained.

After opening the airlocks to allow for the free movement of materials and equipment, workers remove 960 feeder tubes from the reactor.

Feeder tubes carry heated heavy water to boilers and return the water back to the reactor for reheating.

Removal of the feeders is the first step in the disassembly of

the unit, and sets the stage for replacement of parts.

Fuel channels are made of several components: a pressure tube, two stainless steel end-fittings and annulus spacers, which separate the pressure tube from the calandria tubes, preventing them from touching.

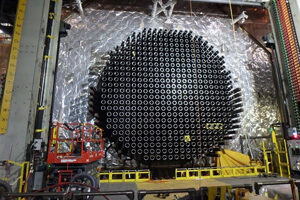

Once all end fittings have been taken out, workers remove all 480 pressure tubes through a process that involves these of engineered tooling mounted on a massive Re-tube Tooling Platform, inside the vault.

A calandria tube is a long cylindrical tube made of zirconium that surrounds the pressure tube and forms a leak tight seal of the calandria vessel – the heart of the reactor.

A Darlington CANDU reactor contains 480 calandria tubes, which are removed using specialized tooling, which workers operate remotely and transport in protective flasks to OPG’s Re-tube Waste Processing Building for storage preparation.

With all the reactor components removed, workers carefully clean and inspect the calandria vessel to ensure materials show no degradation.

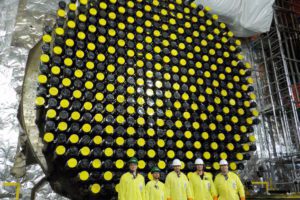

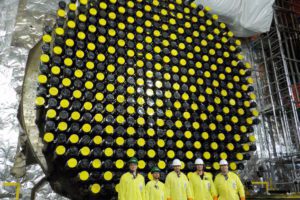

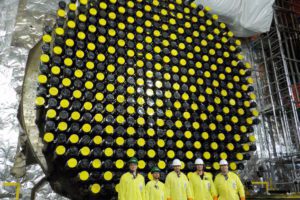

Once this process is complete, workers install 480 new calandria tubes inside the reactor.

Workers complete much of this work manually and directly on the face of the reactor, with direction provided by operators in our Re-tube Control Centre.

After installation, inspection and testing, workers reattach the bellows assemblies, which allow for any movement of pressure tubes and calandria tubes, caused by temperature changes.

Fuel channels are made of several sub-components: a pressure tube, two stainless steel end-fittings and annulus spacers.

The reactor’s 480 fuel channels are critical parts of the heat transport system, which hold the reactor’s fuel bundles.

At this stage, workers pre-assemble the fuel channels in a climate- and foreign material-controlled clean room then prepare them for delivery to the vault for installation.

Each of the reactor’s 960 feeder tubes is unique in shape, size and length, and these new components are delivered in three sections: upper, middle and lower. Because of their unique composition, installing them inside the reactor is a process similar to putting together a puzzle.

Starting with upper section, workers install feeder tubes, making their way down to the lower section, where the feeder tubes are attached to end fittings.

Once this work is complete and regulatory approval received, the project team fills the moderator with clean heavy water and prepares to load the reactor with new fuel.

At this stage, workers refill the moderator with heavy water, load each of the 6,240 fuel bundles into the fuel channels, then fill and pressurize the heat transport system.

A fuel bundle contains natural uranium in the form of ceramic pellets.

Unit containment is restored once we’ve removed all tooling, including the Re-Tube Tooling Platform, needed to perform refurbishment; the airlocks have been closed; the physical barriers removed from inside the vault; and the 59 key systems have been returned to service.

Operators in the Re-Tube Control Centre can then begin the process of achieving first criticality, which means sustaining the chain reaction of splitting atoms and releasing heat.

Throughout refurbishment, the Canadian Nuclear Safety Commission carries out inspections and grants approvals for the project to progress from one milestone to the next. At this stage, the CNSC continues this oversight, confirming the newly refurbished unit can be operated safely and granting approval for the reactor to be gradually brought back to full power and reconnected to Ontario’s power grid.

Following years of detailed planning, approvals and preparations, the Darlington Refurbishment Project team carries out the first major step in project execution: Shutting down the reactor and disconnecting it from the power grid. This is done through a process also known as ‘breaker open,” which involves cooling the reactor and stopping nuclear fission in accordance with Canadian Nuclear Safety Commission regulations and operational procedures.

Now that the reactor has been safely shut down and the reactor disconnected, workers use remote-controlled tooling to remove 6,240 fuel bundles from the unit and place them in water-filled fuel bays for up to ten years of safe storage. Once the fuel has been removed, workers drain heavy water from the reactor and the heat transport system, then store, clean and purify it before pumping it back in, after unit reassembly.

With the fuel and heavy water removed, the unit undergoing refurbishment must be separated from the operating plant. This is done through a process known as Islanding, whereby workers disconnect equipment and put physical barriers in place.

Islanding allows the unit to be refurbished safely and efficiently while limiting impact on the operating units and rest of the station.

Workers perform a containment pressure test at this stage to confirm that the disconnected unit has been safely and completely isolated from the rest of the operating plant.

This process involves raising the pressure in the unit to ensure that any contamination is contained.

After opening the airlocks to allow for the free movement of materials and equipment, workers remove 960 feeder tubes from the reactor.

Feeder tubes carry heated heavy water to boilers and return the water back to the reactor for reheating.

Removal of the feeders is the first step in the disassembly of

the unit, and sets the stage for replacement of parts.

Fuel channels are made of several components: a pressure tube, two stainless steel end-fittings and annulus spacers, which separate the pressure tube from the calandria tubes, preventing them from touching.

Once all end fittings have been taken out, workers remove all 480 pressure tubes through a process that involves these of engineered tooling mounted on a massive Re-tube Tooling Platform, inside the vault.

A calandria tube is a long cylindrical tube made of zirconium that surrounds the pressure tube and forms a leak tight seal of the calandria vessel – the heart of the reactor.

A Darlington CANDU reactor contains 480 calandria tubes, which are removed using specialized tooling, which workers operate remotely and transport in protective flasks to OPG’s Re-tube Waste Processing Building for storage preparation.

With all the reactor components removed, workers carefully clean and inspect the calandria vessel to ensure materials show no degradation.

Once this process is complete, workers install 480 new calandria tubes inside the reactor.

Workers complete much of this work manually and directly on the face of the reactor, with direction provided by operators in our Re-tube Control Centre.

After installation, inspection and testing, workers reattach the bellows assemblies, which allow for any movement of pressure tubes and calandria tubes, caused by temperature changes.

Fuel channels are made of several sub-components: a pressure tube, two stainless steel end-fittings and annulus spacers.

The reactor’s 480 fuel channels are critical parts of the heat transport system, which hold the reactor’s fuel bundles.

At this stage, workers pre-assemble the fuel channels in a climate- and foreign material-controlled clean room then prepare them for delivery to the vault for installation.

Each of the reactor’s 960 feeder tubes is unique in shape, size and length, and these new components are delivered in three sections: upper, middle and lower. Because of their unique composition, installing them inside the reactor is a process similar to putting together a puzzle.

Starting with upper section, workers install feeder tubes, making their way down to the lower section, where the feeder tubes are attached to end fittings.

Once this work is complete and regulatory approval received, the project team fills the moderator with clean heavy water and prepares to load the reactor with new fuel.

At this stage, workers refill the moderator with heavy water, load each of the 6,240 fuel bundles into the fuel channels, then fill and pressurize the heat transport system.

A fuel bundle contains natural uranium in the form of ceramic pellets.

Unit containment is restored once we’ve removed all tooling, including the Re-Tube Tooling Platform, needed to perform refurbishment; the airlocks have been closed; the physical barriers removed from inside the vault; and the 59 key systems have been returned to service.

Operators in the Re-Tube Control Centre can then begin the process of achieving first criticality, which means sustaining the chain reaction of splitting atoms and releasing heat.

Throughout refurbishment, the Canadian Nuclear Safety Commission carries out inspections and grants approvals for the project to progress from one milestone to the next. At this stage, the CNSC continues this oversight, confirming the newly refurbished unit can be operated safely and granting approval for the reactor to be gradually brought back to full power and reconnected to Ontario’s power grid.

Following years of detailed planning, approvals and preparations, the Darlington Refurbishment Project team carries out the first major step in project execution: Shutting down the reactor and disconnecting it from the power grid. This is done through a process also known as ‘breaker open,” which involves cooling the reactor and stopping nuclear fission in accordance with Canadian Nuclear Safety Commission regulations and operational procedures.

Now that the reactor has been safely shut down and the reactor disconnected, workers use remote-controlled tooling to remove 6,240 fuel bundles from the unit and place them in water-filled fuel bays for up to ten years of safe storage. Once the fuel has been removed, workers drain heavy water from the reactor and the heat transport system, then store, clean and purify it before pumping it back in, after unit reassembly.

With the fuel and heavy water removed, the unit undergoing refurbishment must be separated from the operating plant. This is done through a process known as Islanding, whereby workers disconnect equipment and put physical barriers in place.

Islanding allows the unit to be refurbished safely and efficiently while limiting impact on the operating units and rest of the station.

Workers perform a containment pressure test at this stage to confirm that the disconnected unit has been safely and completely isolated from the rest of the operating plant.

This process involves raising the pressure in the unit to ensure that any contamination is contained.

After opening the airlocks to allow for the free movement of materials and equipment, workers remove 960 feeder tubes from the reactor.

Feeder tubes carry heated heavy water to boilers and return the water back to the reactor for reheating.

Removal of the feeders is the first step in the disassembly of

the unit, and sets the stage for replacement of parts.

Each of the 480 fuel channels are made of the following components: two stainless steel endfittings on each side of the reactor vessel, an 8-metre pressure tube running the full length inside the reactor, and several annulus spacers wrapped around each pressure, tube preventing contact with the surrounding calandria tube.

The 960 endfittings are carefully severed at the face of the reactor, transported to a special reactor component processing facility and stored in shielded containers at a secure onsite storage building.

A calandria tube is a long cylindrical tube made of zirconium that surrounds the pressure tube and forms a leak tight seal of the calandria vessel – the heart of the reactor.

Once all endfittings have been taken out, workers remove the 480 calandria tube-pressure tube pairs together through a process that involves unique engineered and remotely-operated tooling mounted on a massive Retube Tooling Platform inside the vault, and then placed into protective flasks and transport in protective flasks to OPG’s Re-tube Waste Processing Building for storage preparation.

With all the reactor components removed, workers carefully clean and inspect the calandria vessel to ensure materials show no degradation.

Once this process is complete, workers install 480 new calandria tubes inside the reactor.

Workers complete much of this work manually and directly on the face of the reactor, with direction provided by operators in our Re-tube Control Centre.

After installation, inspection and testing, workers reattach the bellows assemblies, which allow for any movement of pressure tubes and calandria tubes, caused by temperature changes.

Fuel channels are made of several sub-components: a pressure tube, two stainless steel end-fittings and annulus spacers.

The reactor’s 480 fuel channels are critical parts of the heat transport system, which hold the reactor’s fuel bundles.

At this stage, workers pre-assemble the fuel channels in a climate- and foreign material-controlled clean room then prepare them for delivery to the vault for installation.

Each of the reactor’s 960 feeder tubes is unique in shape, size and length, and these new components are delivered in three sections: upper, middle and lower. Because of their unique composition, installing them inside the reactor is a process similar to putting together a puzzle.

Starting with upper section, workers install feeder tubes, making their way down to the lower section, where the feeder tubes are attached to end fittings.

Once this work is complete and regulatory approval received, the project team fills the moderator with clean heavy water and prepares to load the reactor with new fuel.

At this stage, workers refill the moderator with heavy water, load each of the 6,240 fuel bundles into the fuel channels, then fill and pressurize the heat transport system.

A fuel bundle contains natural uranium in the form of ceramic pellets.

Unit containment is restored once we’ve removed all tooling, including the Re-Tube Tooling Platform, needed to perform refurbishment; the airlocks have been closed; the physical barriers removed from inside the vault; and the 59 key systems have been returned to service.

Operators in the Re-Tube Control Centre can then begin the process of achieving first criticality, which means sustaining the chain reaction of splitting atoms and releasing heat.

Throughout refurbishment, the Canadian Nuclear Safety Commission carries out inspections and grants approvals for the project to progress from one milestone to the next. At this stage, the CNSC continues this oversight, confirming the newly refurbished unit can be operated safely and granting approval for the reactor to be gradually brought back to full power and reconnected to Ontario’s power grid.

A smart investment

According to an independent report by the Conference Board of Canada, the Darlington Refurbishment Project and the subsequent 30 more years of station operation, are expected to generate a total of $89.9 billion in economic benefits for Ontario, create 14,200 jobs per year, and boost personal income by an average of $1.6 billion on an annual basis.

With 96% of project costs spent in the province and a heavy reliance on Ontario-based contractors, for every $1 spent on the project, Ontario’s GDP will increase by an average of $1.40.

In addition to playing a significant role in strengthening Ontario’s economy, an independent report prepared by Intrinsik Environmental Sciences, noted that the continued operation of Darlington Nuclear to 2055 will take the equivalent of two million cars off Ontario’s roads per year by avoiding significant greenhouse gas emissions. This is an important step in Ontario and Canada’s fight against climate change.

Subscribe and stay informed

Sign up to receive the latest news, project updates, and event information from OPG.