Darlington Refurbishment team achieves a first in the nuclear industry

OPG’s Darlington Refurbishment Project is now home to the world’s first combined removal of calandria and pressure tubes.

The first-of-its-kind work on Darlington’s Unit 3 was completed on schedule on Oct. 27, in 30 days, thanks to collaboration by OPG, the SNC-Lavalin Aecon Joint Venture, Canadian Nuclear Laboratories (CNL), CANDU Energy, and Promation Nuclear.

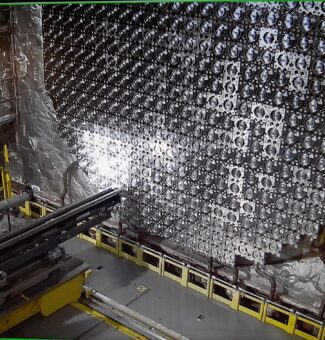

With past CANDU reactor refurbishments, including on Unit 2, Darlington’s first unit to undergo refurbishment, pressure tubes and calandria tubes were individually removed, which was the long-standing practice. Pressure tubes contain the fuel bundles and primary coolant in a reactor, while calandria tubes contain the pressure tubes as well as garter springs nestled between the pressure tube and calandria tube.

Traditionally, the removal of each individual tube, 960 tubes in total, one by one, took approximately 74 days. In addition, the garter springs, which serve as spacer components to maintain the critical gap between the pressure tube and calandria tube, would often become separated from the tubes and proved to be a challenge during work on Unit 2.

The proverbial light bulb moment came in 2018, while planning for Unit 3’s refurbishment. The project team realized it may be possible to adapt a new capability to the existing reactor disassembly toolset to remove the pressure tubes and calandria tubes at the same time.

“The Darlington Refurbishment project team’s drive to continuously improve led to a concept that has now been successfully implemented in the field. More importantly, the team demonstrated outstanding teamwork and collaboration to deliver the work safely and with quality.”Subo Sinnathamby, Senior Vice President of Nuclear Refurbishment

Performing the removal simultaneously would save 30 days per unit, a significant financial savings for the overall project, and largely eliminate the garter spring handling challenges experienced on Unit 2.

“The Darlington Refurbishment project team’s drive to continuously improve led to a concept that has now been successfully implemented in the field,” said Subo Sinnathamby, Senior Vice President of Nuclear Refurbishment. “More importantly, the team demonstrated outstanding teamwork and collaboration to deliver the work safely and with quality.”

By removing both tubes simultaneously and containing the spring spacers, the radiation exposure for personnel performing the work was also reduced by half.

Proof-of-concept tests confirmed the innovative new removal tool could accommodate both tubes, support the extra weight, and safely navigate past other reactor components.

After fabrication and an extensive testing program on a mock-up, training was updated to reflect the new process and the team rehearsed with the new toolset before putting it all to the ultimate test in the Unit 3 vault.

“Fuelled by our lessons learned on Unit 2, the team seized the opportunity with an open and collaborative approach, which led to an elegant solution that would drive great benefits for the project and possibly to the whole nuclear industry,” said CanAtom Program Director Chris Goodwin. “The new removal tool, along with the team’s resourcefulness and commitment, have proven to be a ground-breaking asset to the project and we look forward to ongoing innovation as we complete Darlington’s refurbishment.”

With this work now complete, the project team is set to begin Unit 3’s reassembly phase while preparing to commence refurbishment on Unit 1, planned for February 2022.

Once completed in 2026, the four-unit Darlington Refurbishment will deliver 30 more years of clean power and help OPG and the province achieve its future net-zero goals.

A first in the nuclear industry

Darlington Refurbishment team performs the first-ever combined pressure tube-calandria tube removal.

Subscribe and stay informed

Sign up to receive the latest news, project updates, and event information from OPG.